Types and Uses of CAD Software Systems

Introduction- What is Computer-Aided Design?

Computer-aided design (CAD) is a computerized approach for creating 2D and 3D drawings and models that has mostly replaced manual drafting in a variety of sectors. Designers may use CAD software tools to explore design ideas, readily tweak designs, visualize concepts through renderings. Model how a design operates in the real world, generate documentation, share designs for feedback, and more. All of which helps organizations innovate and come to market quicker.

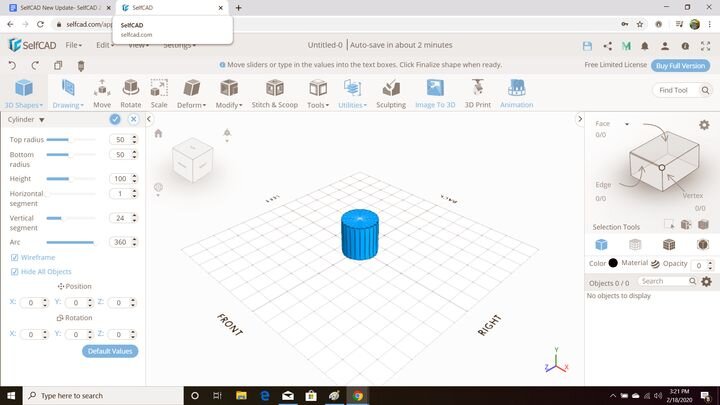

Most modern CAD systems are hybrids, combining elements and tools from a variety of CAD modelling methodologies to meet the needs of a certain sector or product type. SolidWorks and Cobalt excel at solids, but they also have incredible surface capabilities. Mesh modelling and solid modelling are combined in SelfCAD and Fusion360. Even ZBrush is a hybrid system in that it provides superb polygonal modelling tools in addition to a lump of virtual clay to work with.

How are these software’s being used?

In this post, we’ll refer to CAD as any software that can create usable 3D models for manufacturing techniques like injection molding, thermoforming, or 3D printing. The level of parametric control is, in the end, a programme parameter that the designer might choose to use.

Modifiers/deformers that function on the complete shape, such as bending, twisting, smoothening, and morphing forms, are also available. Although portions remain independent of all other model sections, this gives the designer considerable numerical control.

Industrial uses

Many sectors now consider 3D modelling software to be a necessary tool. On the site, we’ve previously chosen CAD software for a variety of purposes. In this article, we’ll look at the finest design software for industrial engineers to use while creating technical parts for mechanical engineering projects. We’ll also examine how 3D visualization and 3D printer software may help with mechanical engineering tasks.

3D printer software is a fantastic manufacturing technology for prototype and production. Indeed, you will simply need to utilize 3D modelling software and make all of the necessary changes to develop a 3D drawing gradually.

You might be able to work straight for production if you use mechanical engineering design software. You may even design extremely intricate pieces using a variety of materials. Metal 3D printing is also an option since it allows for the creation of extremely precise, heat-resistant, and well-designed parts.

Rendering in 3d

Some rendering features in 3D software are quite fantastic. You may gain a better picture of your project by using visualization software or 3D modelling software with strong visualization tools. Indeed, having a clear and exact picture of a technological project before starting. This production process will help you to change and enhance your products quickly. It’s also a wonderful way to catch any last-minute mistakes you could have made during 3D modelling.

3d space and 3d drawings

The software creates a virtual 3D space in which the designer may construct items by entering coordinates into the computer and modifying the forms that those coordinates produce. Frequently, designs begin as simple polygons that designers polish into complicated patterns. By utilizing the tools provided in their chosen programme, such as spline curve creation tools and non-rational b-spline creation tools.

Tangent surfaces are those that flow straight into each other. Programs like Alias, Creo, and Rhinoceros provide advanced surface modelling capabilities in the G2 range. Only the most powerful software solutions, like as CATIA, are adequate for this surfacing. When choosing a surface modeller, keep in mind if the engine is based on NURBS, Bézier, T-Splines, or the obsolete Coons-type definitions.

In contrast to direct modellers, parametric modellers provide the designer complete control over the modelling process. These components stack on top of one another to form a historical model tree that depicts the model’s construction. Rather than working on the geometry itself, the designer focuses on the characteristics that drive the design. Parametric modellers make the most of CAD, but they constantly consider if it obstructs conceptual development.

Verdict

3D modelling’s worth and demand in the job market have expanded as a result of its numerous uses. Despite the fact that 3D modelling and animation is still a developing business, job opportunities and associated career possibilities are expected to expand in the future.

Every day, new applications and uses for 3D models are discovered in many fields. This is how it becomes a valuable tool for young people to utilize in the future, regardless of the job route they select.

Aside from the large market for 3D modellers and animators and future employment options, 3D modelling builds essential life skills for children. This strategy improves problem-solving abilities and inventiveness. When you learn to 3D model, your visual and mathematical skills are substantially enhanced.